______ END ______

| NAS 9300-007 - LOTAR | Reference | 2018 |

| 3D Model Based Definition | 3D MBD |

|

| Model Based Definition (MBD) is a set of concepts, processes, and tools that allow the creation of an annotated 3D product definition based on a 3D solid model. The MBD dataset includes all Engineering Intent requirements (including Process Specifications, Geometric Dimensioning & Tolerancing (GD&T), and other required information). Combined with product lifecycle management (PLM) attributes, a parts list, and general notes, this constitutes an authoritative, single source of master product definition data that does not include or depend upon traditional 2D drawings. The MBD dataset defines complete requirements for a product in its nominal condition as well as permissible limits of variation and other acceptance criteria, providing all the data needed to plan, fabricate, and validate an article of product hardware. |

| The collection of abstractions, assumptions, and descriptions of physical processes representing the behavior of the reality of interest from which the mathematical model or validation experiments can be constructed (adapted from ASME V&V 10). |

| The essential minimum of data which are required to preserve the design intent for a given purpose. (NAS9300-003, 5.3.2.1) |

| A collection of data treated as a single unit, such as a CAD model or file. |

| A digital signature with which the data producer asserts that the prepared data fits with the process and quality requirements from the engineering point of view. (NAS9300-005) |

| Storage of a copy of data in an appropriate way for record, certification and legal purposes. The data will be preserved and kept available for a use within the archive and possibly for further re-use. With certified conversion processes, the native data representation generated by the source system can be converted into a representation which is appropriate for long term archiving. To fulfill legal and certification requirements, the stored form can be an accurate or approximate representation of the source. Integrity must be ensured by a digital signature. The data is retained over the long term. Invariance is mandatory. Business, legal and certification requirements are covered. (NAS9300-003, 3.2.5) |

| Data about data. For example, the file name is meta data about a CAD design held as a file. |

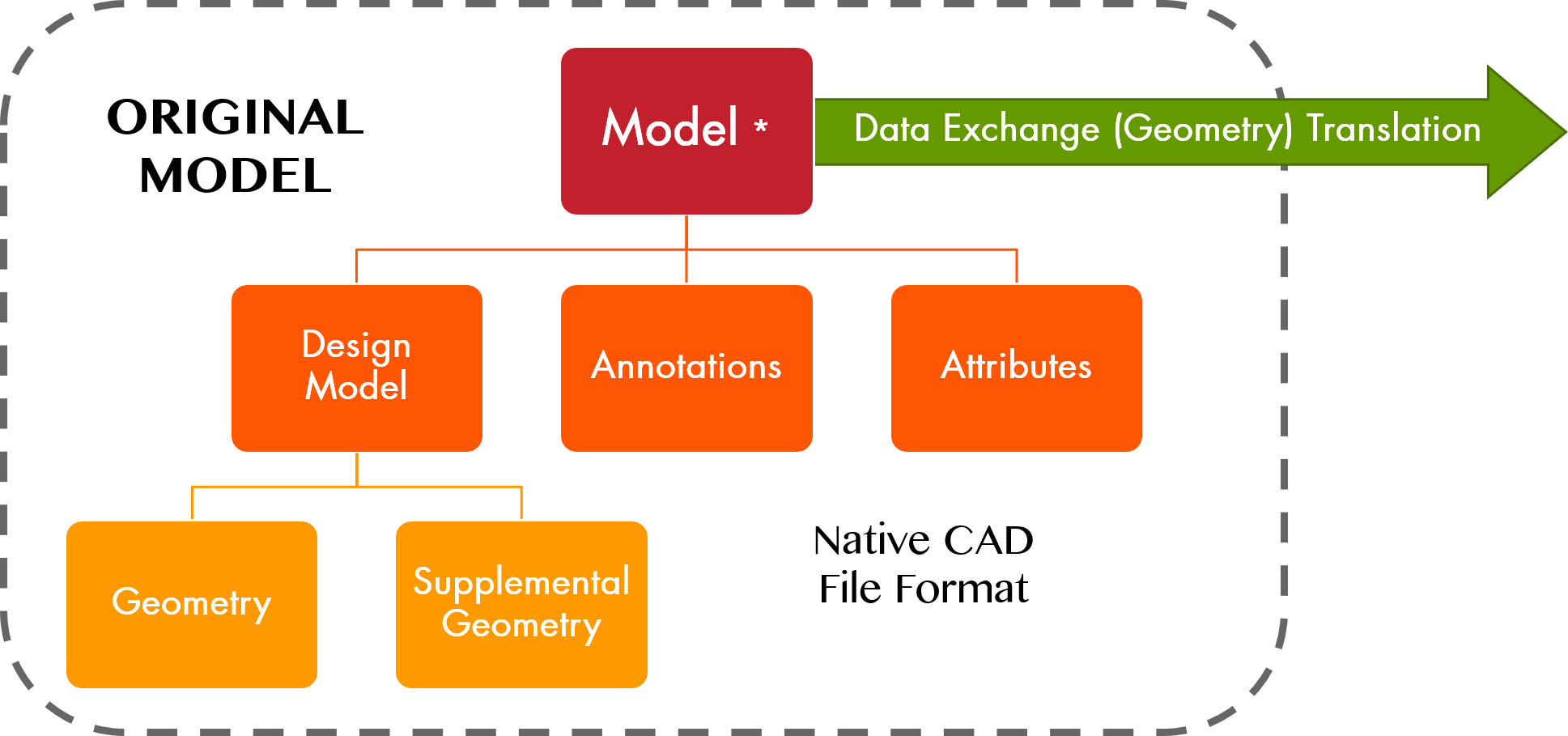

| The portion of the data set that contains model geometry and supplemental geometry. |  |

| The format in which a software application stores its data, where that format is part of the design of the software. |

| The model used to keep the design intent for Long Term Archiving in the context of certification & legal requirements for proof. |

| Product Definition Data, Technical Data, Item, Feature, Drawing, Item. IdentificationIncludes materials, parts, components, subassemblies, assemblies, and equipment. The term product shall also encompass a family of products. |

| A representation of information about a product in a formal manner suitable for communication, interpretation, or processing by human beings or by computers. |

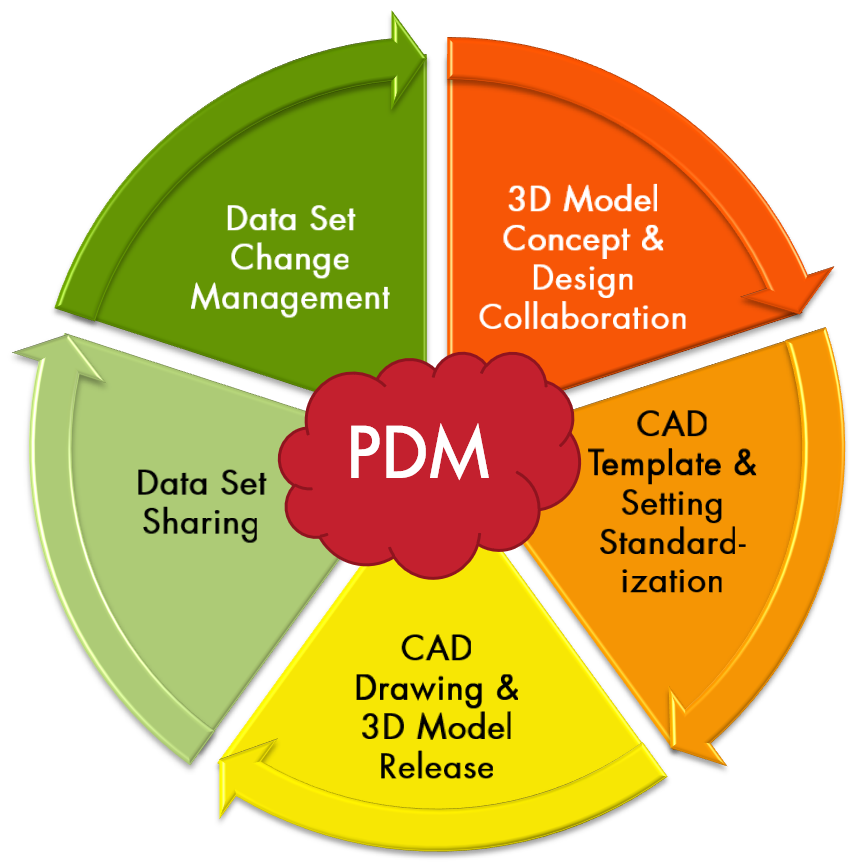

| A system that manages as-designed data and is the authoritative source for the geometry, attributes, CAD BOM, and revision. |  |

| The product information model is an information model which provides an abstract description of facts, concepts and instructions about a product, such as a STEP Application reference model or STEP Application interpreted model. (cf NAS9300-003, 3.2.1) |

| A system that manages as-built design information and is the authoritative source for the eBOM, changes, data package, design deviations, and usage. |  |

| 3D annotations (dimensions and tolerances), metadata, notes and attributes needed to define the product beyond the 3D geometry. |

| The manner in which information is stored for interpretation by a machine. |

| Information calculated from a model or document whose invariance is used to validate the content after recovery, and so to demonstrate that the key characteristics are unchanged. For example, the volume of a solid in a CAD file. |

| The model used for creation and modification by the native application; it corresponds generally to the design stage of the Product Model; this Working Form is often in the native format of the COTS application. |